Rising damp

PROTECT YOUR MASONRIES AND

TREAT THEM SIMPLY AGAINST RISING DAMP.

Damage: humidity in walls

What rising damp means?

A rising damp sign is often a visible tide-mark about 1m above floor level.

Rising dampness is one of the main cause of dampness in buildings.

Most walls in new buildings have a physical barrier or damp proof course to prevent rising dampness, however, in older buildings or if the physical barrier has broken down, it is important to install a remedial damp proof course (DPC).

During the diagnosis, the surveyor must make sure the damp problem doesn’t come from another damp issue such as plumbing defects, condensation or penetrating damp (rain water ingress).

How to stop rising damp? See our method below.

Damage of rising dampness: humidity in walls

Saltpeter, mold and fungus

A high humidity rate significantly promotes the development of molds and fungi.

The saltpeter is deposited on the surface of the wall in the form of white crystals of cottony appearance.

Blistering and degradation

Water, migrating to the inner walls, causes the blistering and peeling of decorative paints and coatings.

The salt stained plaster loses its hardness and adhesion. Decayed skirting boards and timber floors.

Rising damp treatment method by injection

The water in the soil rises naturally into the masonry and causes important degradations. Act in depth, for lasting results.

Rising damp can be cured by the installation of a chemical damp proof course.

Damp proofing keeps moisture out of a building thanks to the injection of a product to reduce the moisture transfer via capillary pores. Various active principles are available depending on the result needed, from a complete closure of the pores to pore hydrophobizing (Siliconate, Silicone Alcali silicate, Silane/Siloxane, Acrylate gel…).

What you need to install a remedial damp proof course (DPC):

- Concrete drill bits

- Mabi injectors diameter 12, 14 or 18mm (injection packers)

- Mabi pump with an injection tip

- DPC solution

- Personal Protective Equipment (PPE)

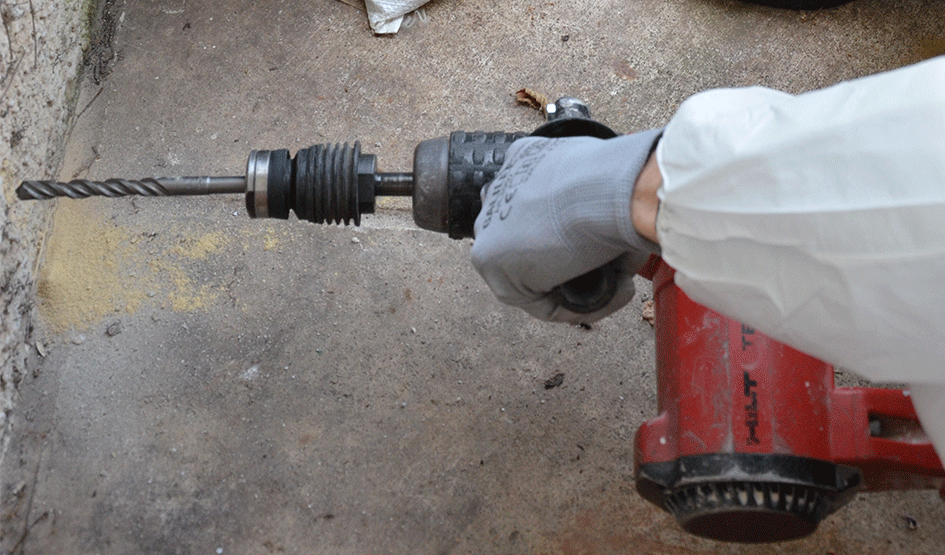

Drill

To prepare the rising damp treatment, all coatings have to be removed; and brittle or non-adhesive parts located into the injection zone have to be brushed.

If the walls have many cavities or voids, prefilling these parts with a suitable non-shrinkable filler before the damp proof course injection is needed.

The injection holes have to be drilled on the outside, following a horizontal line or are placed in a staggered row in order to create a double chemical barrier.

Drilling is about 10cm above ground, in the mortar beds, spacing between boreholes is about 10/15cm and 2/3rd of the wall thickness.

Drill bits are available here

Injection-packers’ implementation

Plastic injection-packers are inserted into each injection hole, using a hammer and a mounting tool. The packers have been developed to keep enough pressure during and after the injection; to obtain an optimal diffusion of the damp proof course chemical into the thickness of the wall. It’s recommended to use diffusing tubes with the packers. Diffusing tubes have 360° micro holes, are driven into the thickness of the wall and adapt themselves at the bottom of the packer.

Injectors, also called injection packers are available in different sizes in our online shop

Inject

The damp proofing product is injected with low pressure thanks to a gun and the corresponding MABI pump.

Choose your pump depending on your needs here.

With their inner valve system, the Mabi injectors will force the waterproofing liquid solution to spread inside the masonry with no leaks or splash back.

For each injection, the injected product quantity should be controlled in order to respect the manufacturer’s chemical product instructions (DPC solution quantity to be injected per linear meter).

The packers allow an injection into the wall without backflow of chemical from the injected hole or the adjacent bore holes.

Renovate

The product reacts in the masonry to become hydrophobic resin and create a barrier, called a remedial damp proof course (DPC).

After 2-3 weeks the moisture flow is stopped by the chemical barrier. It is then necessary to facilitate at the maximum the drain conditions of the treated masonry (aerate, warm up and dehumidify). Regular monitoring of humidity can follow the progress of drying and renovations begin only when the wall reaches a humidity level inferior to 5%.

Combine this approved method with a Damp Proof Course chemical, for example PCI Bohrlochsperre, Schomburg Aquafin-F , Remmers Kiesol, Bornit SI, Botazit MS10, Kreisel 900, Mapei Mapestop, Mautrol 1K, Sopro VK 690, Weber.tec 940 or any other brand labelled for this application in your country.

The methods are given for information purposes only.

Always refer to the local legislation and to the chemical manufacturer’s label before starting any job.

Always wear the Personal Protective Equipment (PPE) required and officially approved for chemical handling, including gloves, coverall, respirator and protective eyewear.